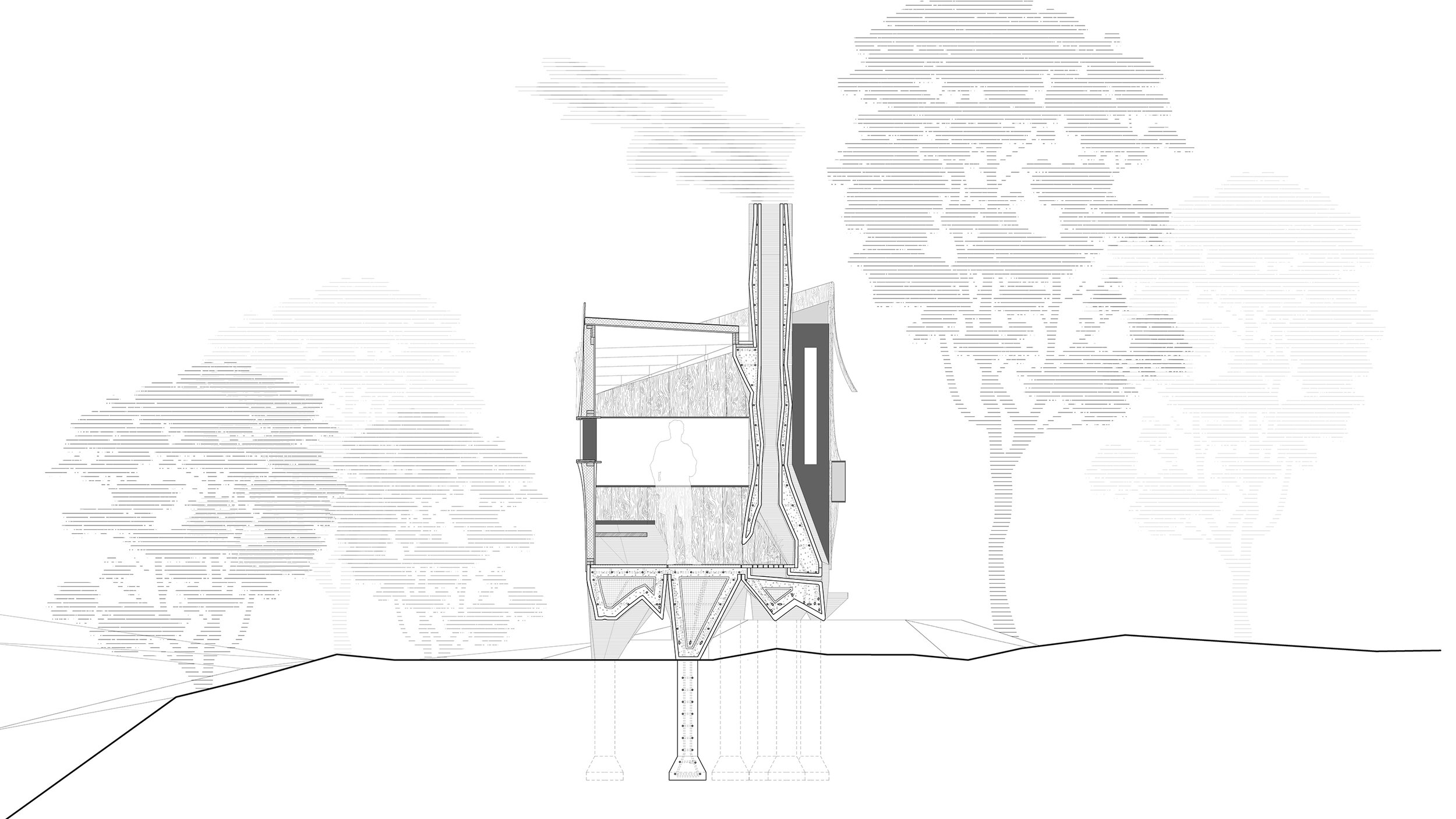

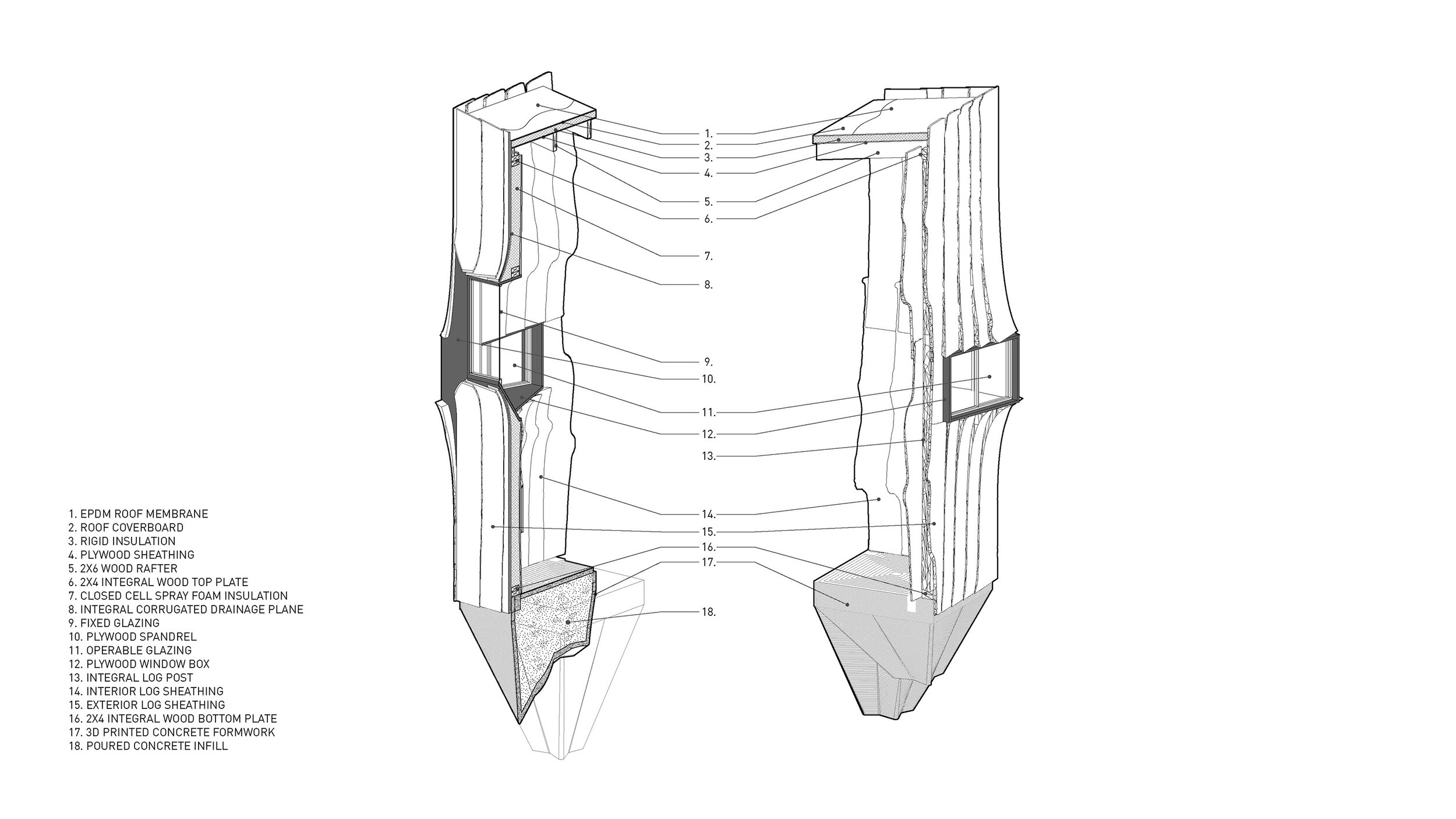

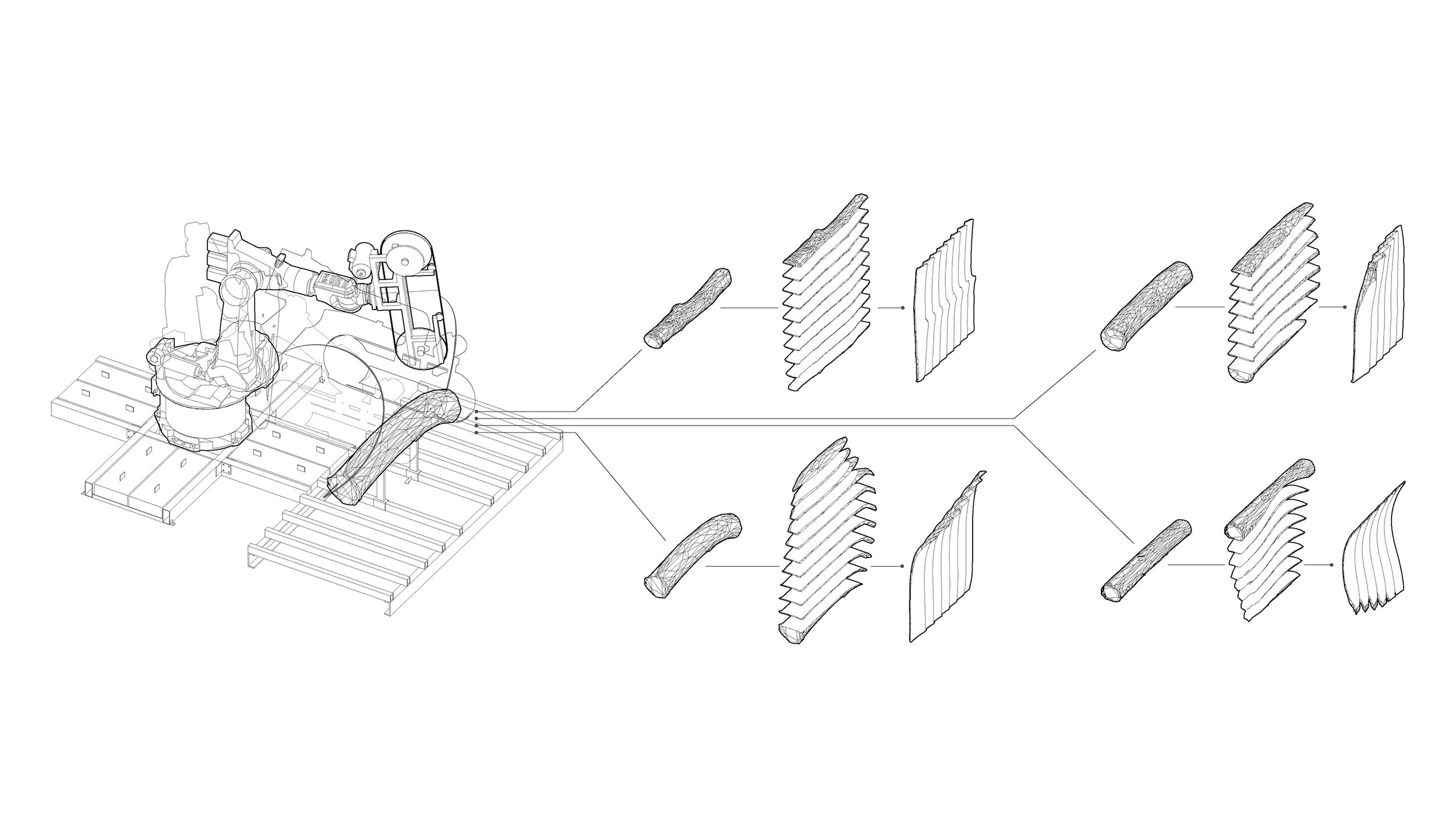

By implementing high precision 3D scanning and robotic based fabrication technology, HANNAH transforms Emerald-Ash-Borer-infested “waste wood” into an abundantly available, affordable, and sustainable building material. From the ground up, digital design and fabrication technologies are intrinsic to the making of this architectural prototype, facilitating fundamentally new material methods, tectonic articulations, and forms of construction.

Ashen Cabin

Ithaca, NY. 2019.

HANNAH project leadership: Leslie Lok and Sasa Zivkovic (Principals) / HANNAH project team concrete: Christopher Battaglia, Jeremy Bilotti, Elie Boutros, Reuben Chen, Justin Hazelwood, Mitchie Qiao / HANNAH assembly and documentation team concrete: Alexandre Mecattaf, Ethan Davis, Russell Southard, Dax Simitch Warke, Ramses Gonzales, Wangda Zhu / HANNAH project team wood fabrication and design: Byungchan Ahn, Alexander Terry / HANNAH wood studies: Xiaoxue Ma, Alexandre Mecattaf / HANNAH assembly and documentation team wood: Freddo Daneshvaran, Ramses Gonzalez, Jiaying Wei, Jiayi Xing, Xiaohang Yan, Jingxin Yang, Sarah Elizabeth Bujnowski, Eleanor Jane Krause, Todd Petrie, Isabel Lucia Branas Jarque, Xiaoxue Ma / HANNAH representation team: Byungchan Ahn, Kun Bi, Brian Havener, Lingzhe Lu

Project realized with scientific support from the Cornell Robotic Construction Laboratory (RCL) / Sponsors: AAP College of Architecture, Art, and Planning; AAP Department of Architecture; HY-Flex Corporation; Cornell Atkinson Center for a Sustainable Future, Cornell Arnot Teaching and Research Forest

Special thanks to: Andrea Simitch and Val Warke.

Photography: Andy Chen, HANNAH